The Widner Mobility Oscillator is a groundbreaking device that changes how we think about movement. This amazing technology helps robots, cars, and smart devices move more smoothly and quickly. Imagine a robot that can dance or a car that drives without bumps this is what the Widner Mobility Oscillator can do.

Developed by clever engineers, the Widner Mobility Oscillator uses special movements to improve how machines work. It makes them faster and more efficient, which is super important for all kinds of industries. From helping robots do delicate tasks to making sure cars have a smooth ride, this technology is transforming our world. The Widner Mobility Oscillator is more than just a tool; it is a big step toward smarter and better machines that can make our lives easier and more fun. With its innovative design and unique capabilities, this device is shaping the future of mobility.

What is the Widner Mobility Oscillator?

The Widner Mobility Oscillator is a special device designed to help machines move better. It creates smooth, oscillating movements that make robots and vehicles more efficient. This oscillator is different from regular ones because it focuses on how things move instead of just repeating the same motions. This is important for industries that need fast and precise movement.

Engineers created this oscillator to solve problems in mobility. For example, it helps robots perform tasks more accurately. It also makes sure that cars can drive smoothly on the road. By using advanced technology, the Widner Mobility Oscillator makes machines work better and last longer. This means less downtime and more productivity in various fields.

Many people use this technology, from robot manufacturers to car companies. The Widner Mobility Oscillator has become a popular choice because it improves how machines operate. It is changing the way we think about movement and efficiency in technology.

How the Widner Mobility Oscillator Works

Understanding how the Widner Mobility Oscillator works can be fascinating! This device uses special principles of oscillation. Oscillation means moving back and forth in a smooth manner. The oscillator controls these movements very precisely, which helps in making machines perform well.

Inside the oscillator, there are advanced parts that control the speed and direction of movement. This helps robots make smooth movements, just like how humans move their arms and legs. The oscillatory motions improve how joints and actuators in robots work. It makes tasks easier, like lifting heavy objects or reaching high places.

Additionally, the oscillator helps reduce energy use. Because it makes movements more efficient, machines do not waste power. This is important for saving money and resources. With the Widner Mobility Oscillator, we can expect machines to be faster, stronger, and smarter, making our lives easier in many ways.

History Behind the Widner Mobility Oscillator

The story of the Widner Mobility Oscillator began with a dream to create better mobility technology. Engineers and researchers wanted to solve problems in how machines move. They realized that traditional oscillators did not meet the growing needs of modern industries. So, they set out to invent something new and better.

After years of hard work, the Widner Mobility Oscillator was born. It was a breakthrough in engineering. The team behind it used their knowledge of robotics and vehicle dynamics to create a device that enhances movement. This oscillator quickly gained popularity in many fields because of its innovative design and superior performance.

Over time, the technology has continued to improve. Researchers have made it more efficient and easier to integrate into existing systems. The history of the Widner Mobility Oscillator is a story of innovation, teamwork, and the desire to push boundaries in technology. Today, it stands as a symbol of what is possible in the world of mobility solutions.

Key Features of the Widner Mobility Oscillator

The Widner Mobility Oscillator has many key features that make it unique. One important feature is its modular design. This means it can be easily added to different machines without much trouble. This flexibility allows engineers to use it in various applications, from robots to vehicles.

Another great feature is its durability. The oscillator is built to last, even in tough environments. This means it can handle challenging conditions without breaking down. Its strong construction ensures that it performs well over time, which is important for companies that rely on consistent results.

Moreover, the advanced control algorithms make the oscillator highly precise. Engineers can adjust the settings to fit specific needs. This ensures that machines operate at their best. Overall, the features of the Widner Mobility Oscillator make it a preferred choice for many industries looking to improve mobility and efficiency.

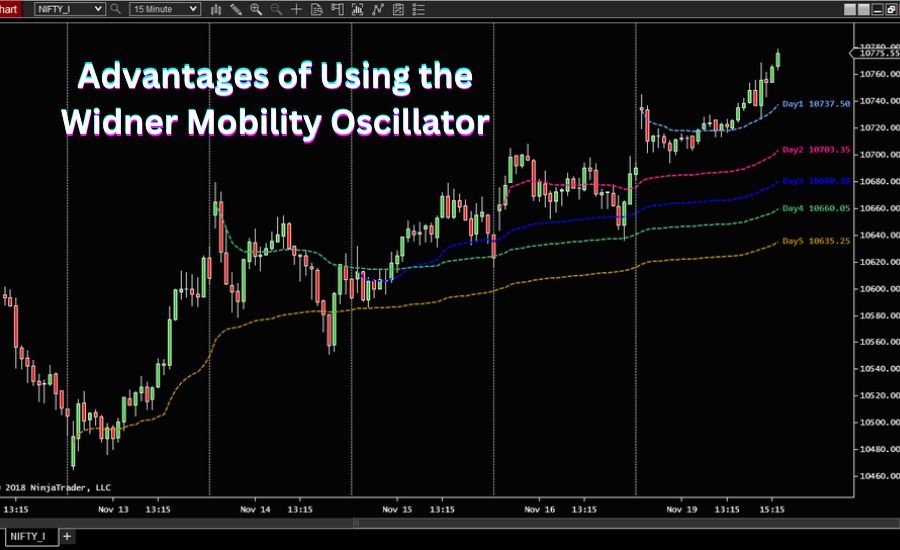

Advantages of Using the Widner Mobility Oscillator

There are many advantages to using the Widner Mobility Oscillator in various industries. First, it improves the performance of machines. With better mobility, robots can work faster and with greater accuracy. This is especially important in industries where precision matters, like healthcare and manufacturing.

Second, the oscillator helps save energy. Because it optimizes movements, machines use less power. This can lead to lower energy bills and a smaller carbon footprint, making it an environmentally friendly choice. Companies looking to be more sustainable can benefit greatly from this technology.

Lastly, using the Widner Mobility Oscillator can reduce maintenance costs. Since it is built to be durable, machines can run longer without needing repairs. This means companies can spend less time and money fixing machines and more time focusing on their work. Overall, the advantages of this oscillator make it an excellent investment for many businesses.

Applications of the Widner Mobility Oscillator in Robotics

In robotics, the Widner Mobility Oscillator is essential for enhancing movement capabilities. It enhances how robots move, allowing them to perform tasks with ease. For example, in factories, robots can pick and place items quickly and accurately. This makes production lines more efficient.

Additionally, the oscillator enables robots to mimic human movements. This is important in fields like healthcare, where robotic arms can assist in surgeries. The precision provided by the Widner Mobility Oscillator ensures that every movement is controlled and accurate, which can be life saving.

Furthermore, in research and exploration, this oscillator allows robots to navigate complex environments. Whether in space or underwater, robots equipped with the Widner Mobility Oscillator can handle challenging tasks that require precise movements. The applications of this technology in robotics are vast and exciting!

Widner Mobility Oscillator in Vehicle Technology

The Widner Mobility Oscillator is also transforming vehicle technology. It enhances how cars and trucks handle different terrains. This means a smoother ride for passengers and drivers. Whether driving on rough roads or city streets, vehicles with this oscillator can adjust their movements to provide comfort and stability.

Moreover, the oscillator improves vehicle safety. By optimizing suspension systems, it helps reduce the risk of accidents caused by rough driving conditions. When a vehicle can adapt quickly, it maintains better control, ensuring a safer experience for everyone inside.

Lastly, the Widner Mobility Oscillator supports the development of electric and autonomous vehicles. As the world moves toward greener technology, this oscillator helps increase the efficiency of electric cars. It can extend battery life and reduce energy consumption, making it a valuable addition to modern vehicle design.

Integration of the Widner Mobility Oscillator with IoT Systems

Integrating the Widner Mobility Oscillator with Internet of Things (IoT) systems is a game changer. This technology allows devices to communicate and share information seamlessly. For example, smart sensors can use the oscillator to gather data more accurately. This is important in smart cities and industrial automation.

By using this oscillator, IoT devices can operate more efficiently. They can analyze data in real time and adjust their actions based on what they learn. This leads to better decision making and improved performance in various applications.

Additionally, the combination of the Widner Mobility Oscillator and IoT systems helps in environmental monitoring. Devices can collect data on weather patterns, pollution levels, and more, leading to smarter solutions for our planet. Overall, the integration of these technologies opens up new possibilities for innovation and efficiency.

Comparing the Widner Mobility Oscillator to Other Devices

When comparing the Widner Mobility Oscillator to other devices, its unique features stand out. Unlike traditional oscillators, which focus mainly on repetitive motions, the Widner oscillator excels at creating smooth, dynamic movements. This makes it more suitable for applications where mobility is key.

Additionally, the advanced control algorithms in the Widner Mobility Oscillator allow for precise adjustments. This flexibility is not always available in other oscillators. As a result, it can adapt to specific requirements across different industries.

Moreover, its modular design makes it easier to integrate into existing systems. Many devices require special modifications to fit new oscillators. However, with the Widner Mobility Oscillator, the process is simpler and more efficient. This versatility makes it a top choice for companies looking to enhance their technology.

Common Issues with the Widner Mobility Oscillator and How to Fix Them

While the Widner Mobility Oscillator is a reliable device, it can still face some common issues. One of the main problems is calibration errors. If the oscillator is not calibrated correctly, it can affect performance. To fix this, users should follow the manufacturer’s guidelines for calibration procedures.

Another issue can be sensor malfunctions. Sensors help the oscillator track its movements. If a sensor stops working, it can cause irregular movements. Regular maintenance and checks on the sensors can prevent this problem. If a sensor is faulty, replacing it quickly can ensure the oscillator continues to function correctly.

Lastly, environmental disturbances can impact how the oscillator works. Factors like extreme temperatures or dust can affect its performance. Keeping the device clean and in a controlled environment can help maintain optimal functionality. By being proactive about these issues, users can ensure their Widner Mobility Oscillator runs smoothly.

Essential Information: Refferral-code-zearn-crypto-referral-code

Installation and Setup of the Widner Mobility Oscillator

Setting up the Widner Mobility Oscillator is an easy task. First, users should carefully read the manufacturer’s guidelines. Understanding these instructions is essential to ensure the oscillator works well with existing systems. Proper installation reduces the likelihood of encountering problems later on.

Next, the setup involves configuring oscillatory parameters. This means adjusting settings to fit specific needs. Users may need to conduct tests to check that everything is working correctly. These tests help validate the performance of the oscillator, ensuring it meets the desired standards.

Finally, once installed, regular checks are crucial. Users should monitor the oscillator’s performance and make adjustments as needed. This proactive approach can lead to better results and longer device lifespan. The installation and setup of the Widner Mobility Oscillator are key steps in maximizing its benefits.

Maintenance Tips for the Widner Mobility Oscillator

Taking care of the Widner Mobility Oscillator is important for keeping it running smoothly. Regular maintenance can prevent issues and extend its lifespan. First, users should clean the device regularly. Dust and debris can affect performance, so keeping it clean is crucial.

Second, checking the calibration often is essential. Over time, the oscillator might need recalibration to maintain accuracy. Following the manufacturer’s guidelines for calibration helps ensure the device operates at its best. Regular checks will help identify any issues before they become serious problems.

Finally, users should keep an eye on the sensors and components. Regular inspections can catch any malfunctions early. If something seems off, addressing it quickly can save time and money in the long run. By following these maintenance tips, users can keep their Widner Mobility Oscillator in excellent shape.

Innovations and Future of the Widner Mobility Oscillator

The Widner Mobility Oscillator represents the future of mobility technology. Engineers and researchers are continually looking for ways to improve it. Innovations like AI integration are on the horizon. By incorporating artificial intelligence, the oscillator can learn from its movements and adjust them automatically for better performance.

Moreover, developments in materials science are helping create even more durable components. Lightweight and strong materials can enhance the oscillator’s efficiency, making it suitable for a broader range of applications. This means more industries will be able to benefit from its advantages.

As technology advances, the Widner Mobility Oscillator will likely find new uses in everyday life. From smart homes to autonomous vehicles, its impact will be far reaching. The future looks bright for this technology, and we can expect exciting innovations that will change how we think about mobility.

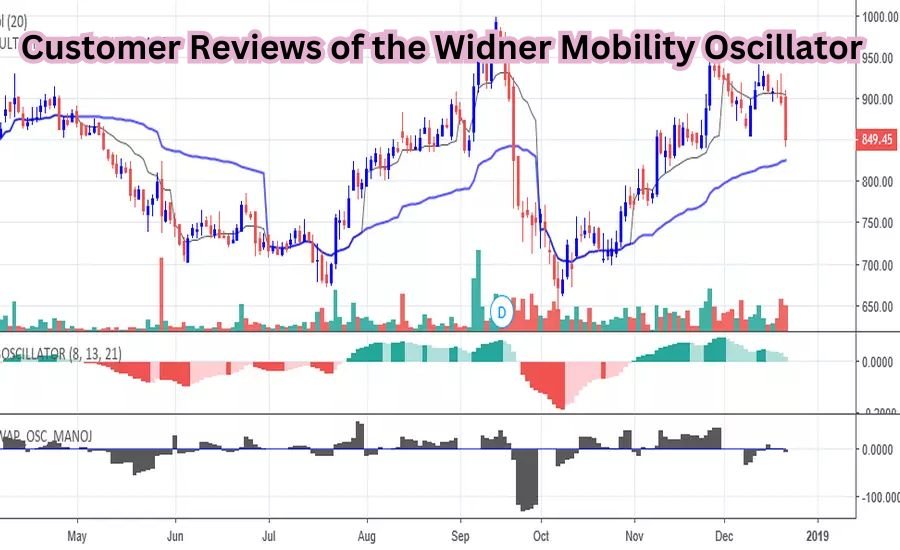

Customer Reviews of the Widner Mobility Oscillator

Customer reviews of the Widner Mobility Oscillator reveal a lot about its performance and value. Many users praise its efficiency and precision. They find that it significantly improves how machines operate, making tasks easier and quicker. Users in the robotics industry, in particular, highlight how it enhances robot movements.

Another common theme in reviews is the ease of integration. Customers appreciate that they can add the oscillator to existing systems without extensive modifications. This saves time and resources, making it a popular choice for businesses looking to upgrade their technology.

However, some users mention the need for proper calibration to achieve optimal results. They emphasize that following the installation guidelines closely is essential. Overall, customer feedback shows that the Widner Mobility Oscillator is a valuable investment for improving mobility technology.

Is the Widner Mobility Oscillator Worth the Investment?

Many businesses wonder if the Widner Mobility Oscillator is worth the investment. The answer depends on the specific needs of each company. However, the benefits it offers are substantial. For companies focused on improving efficiency and mobility, investing in this technology can lead to better productivity and reduced operational costs.

Moreover, the oscillator’s ability to enhance the performance of machines can result in long-term savings. By reducing energy consumption and maintenance needs, businesses can recover their investment over time. The versatility of the Widner Mobility Oscillator makes it applicable in various industries, adding to its appeal.

In conclusion, the Widner Mobility Oscillator is likely a wise investment for those looking to stay ahead in technology. Its innovative design, efficiency, and ease of use make it a standout choice for many applications. Embracing this technology can lead to improved performance and success in an ever changing market.

Conclusion

In conclusion, the Widner Mobility Oscillator is an exciting piece of technology that helps machines move better. It makes robots and vehicles work more efficiently, which is important for many businesses. People in factories, hospitals, and even cars can benefit from its smooth movements. By improving how things move, the oscillator helps save energy and reduce costs. Many customers are happy with its performance, and it has become a popular choice in various industries.

As we look to the future, the Widner Mobility Oscillator will continue to play an important role in making our machines smarter and faster. With new innovations and ideas, we can expect even more exciting developments in mobility technology. Whether it’s in robotics or vehicles, the benefits of this oscillator will help us in our daily lives. So, if you’re looking for a way to enhance movement and efficiency, the Widner Mobility Oscillator might be just what you need.

You Should Be Aware Of: Crypto-facto-fintechasianet

FAQs

What is the Widner Mobility Oscillator?

The Widner Mobility Oscillator is a specialized device that generates smooth and efficient oscillatory movements. It enhances the performance of robotic systems, vehicles, and IoT devices by optimizing how they move.

How does the Widner Mobility Oscillator work?

It operates on advanced principles of oscillation dynamics, using precise control mechanisms to create seamless movements. This improves the agility and responsiveness of machines in various applications.

What are the key features of the Widner Mobility Oscillator?

Key features include a modular design for easy integration, robust construction for durability, and advanced control algorithms that allow for precise adjustments based on specific needs.

What industries benefit from the Widner Mobility Oscillator?

Many industries benefit, including robotics, automotive, and IoT sectors. It helps improve the functionality and efficiency of machines in factories, hospitals, and vehicles.

Is the Widner Mobility Oscillator energy efficient?

Yes, it is designed to minimize energy consumption. By optimizing movement, it can help reduce energy costs and extend the range of electric vehicles.

Can the Widner Mobility Oscillator be integrated with existing systems?

Absolutely! Its modular design allows for easy integration into various systems, ensuring compatibility with current technology without major changes.

What maintenance does the Widner Mobility Oscillator require?

Routine maintenance includes visual inspections for wear and tear, regular lubrication of moving parts, and monitoring oscillatory parameters to ensure optimal performance.